Lens Processing Technology

In the lens processing, in order to manufacture a lens with the required performance, various conditions need to be adjusted by selecting the machine used for manufacturing and adjusting the polishing time according to the magnitude of curvature and the characteristics of the material.

For example, high-pixilation and high-definition are yearly advanced in CMOS image sensor used in cameras and a lens surface-roughness, unevenness or waviness negatively effects the lens imaging performance.

To enable a highly accurate lens, Tamron reflect a simulation result to a processing accuracy from the optical designing stage.

Tamron’s lens processing technology is covering a wide range, multiple lens bonding with curved surfaces, processing with plane lens and prism lens, and prism lens bonding with each other. From now on, as a new usage, optical lens is expected to be used with laser and to be required a complicated irregular shape or prism shape integrating various technologies.

To produce multifarious lenses required in the future, Tamron is newly developing and improving the processing technology and handing down its established expertise by cooperating the lens processing know-how and the optical development technology.

Glass molded optical lens with special form

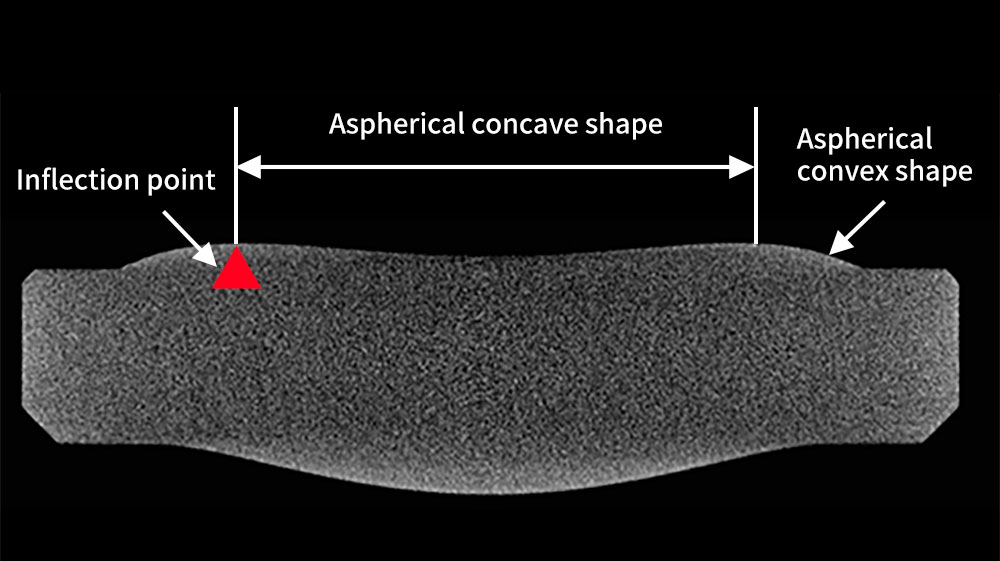

inflection point (seagull wing shaped lens processing)

Various cameras, such as wearable cameras and surveillance cameras, need a higher accurate aberration correction due to image sensor’s high pixilation.

Curved shaped aspherical lenses made by grinding and molding are used for correcting lens aberration.

Changing the point on the ark on curved surface, which is called inflection point, does not exist in general glass molded aspherical lenses and only one lens has a limited ability to correct aberration.

Tamron realized the manufacturing of special formed glass optical molded lens having inflection point which effectively correct a distortion aberration of wide-angle lens and a field curvature aberration of high-resolution lens. In addition to a highly precise forming, one of the features is that general glass materials are acceptable.

Tamron realizes a high quality and stable manufacturing by collaborating highly technical lens design and molding technology and makes it applicable to a wide variety of application.

Technical features

-

FEATURE 1

Technology for manufacturing glass molded lens with inflection point

-

FEATURE 2

Effective in distortion correction for wide angle lens and in field curvature correction for high-resolution lens

-

FEATURE 3

Correspond to glass materials used in general glass molded lenses

-

FEATURE 4

Superior aberration correction performance than conventional glass molded lens

-

Glass molded lens with inflection point

(CT imaging)※Click on the image to enlarge

-

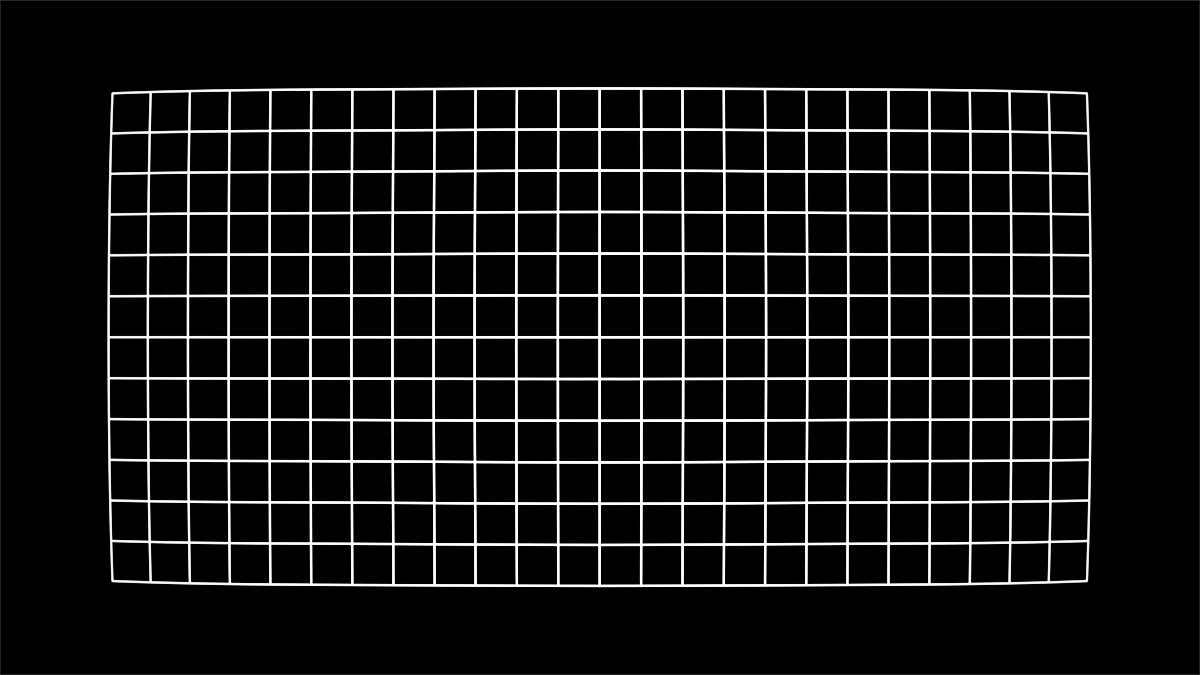

Optical simulation of distortion correction

(100°horizontal angle of view)※Click on the image to enlarge

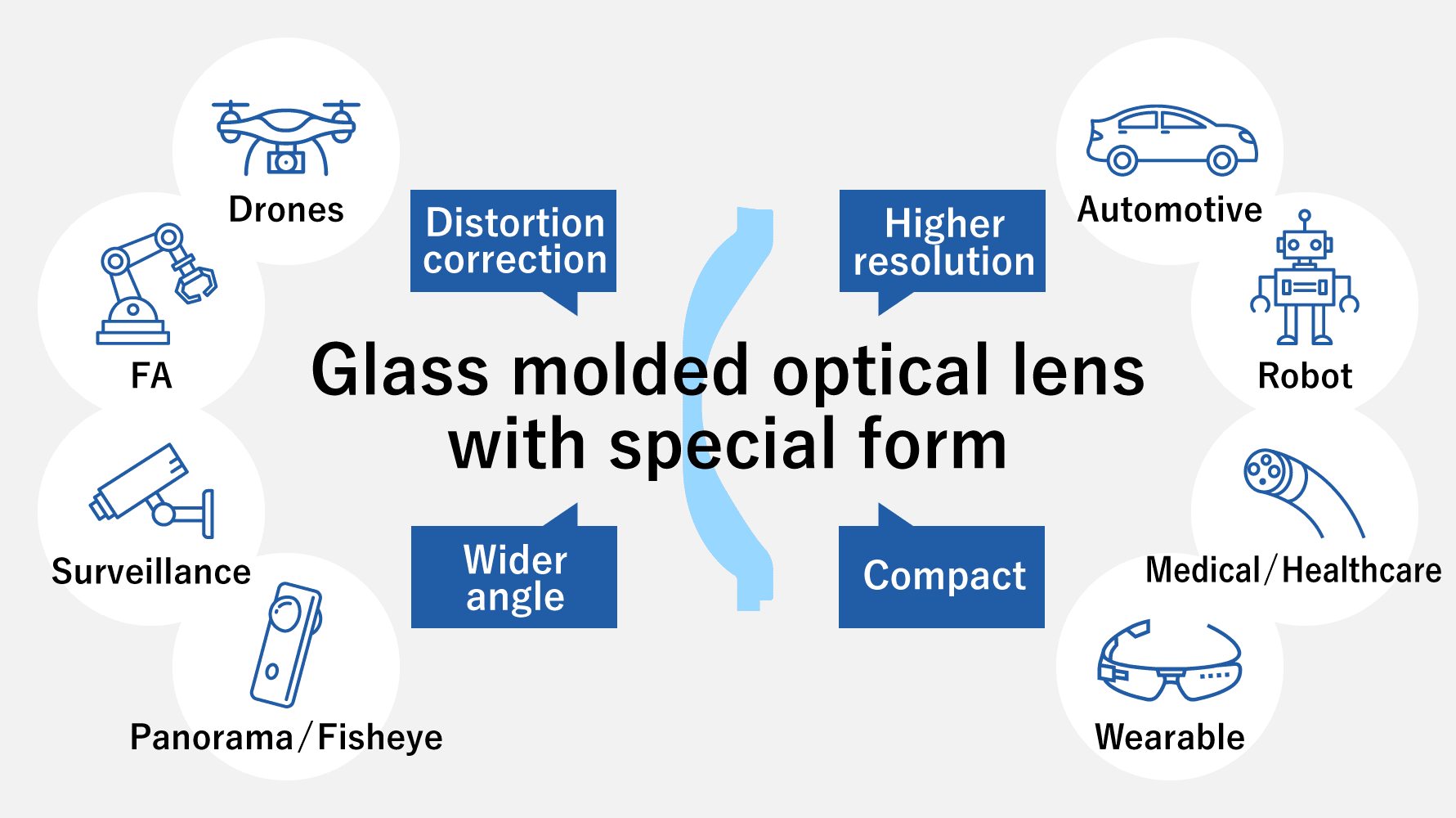

Examples of applications

-

Effect by using seagull wing shaped lens and expected applications

※The photo is for illustrative purposes only.

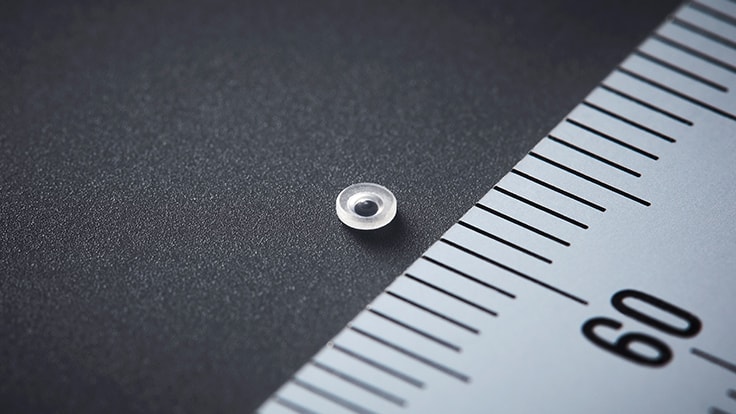

Ultrathin and small diameter glass molded lens

Pursue Thinness and Smallness

Glass molded lenses are made by heating the glass material at a high temperature and pressing it with an elaborate mold made in nanometer units. While the production efficiency is high, it is molded in a thin-walled shape and can sometimes crack. Therefore, an advanced manufacturing process is required.

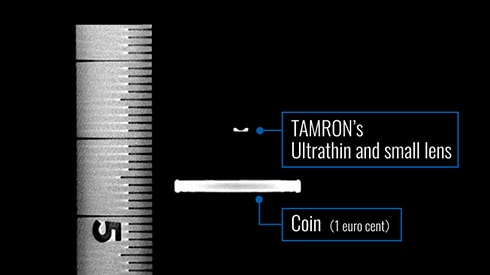

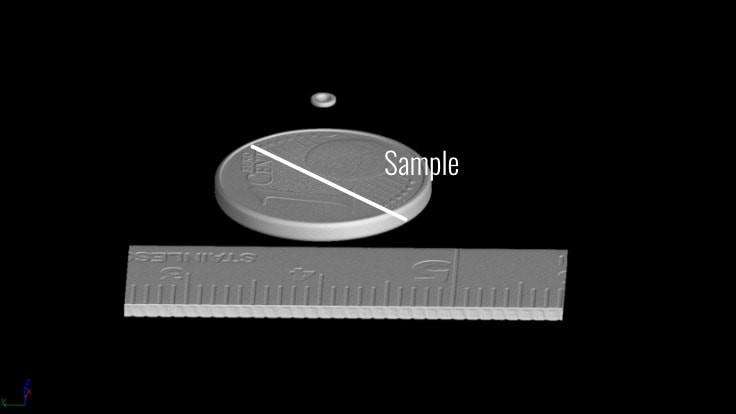

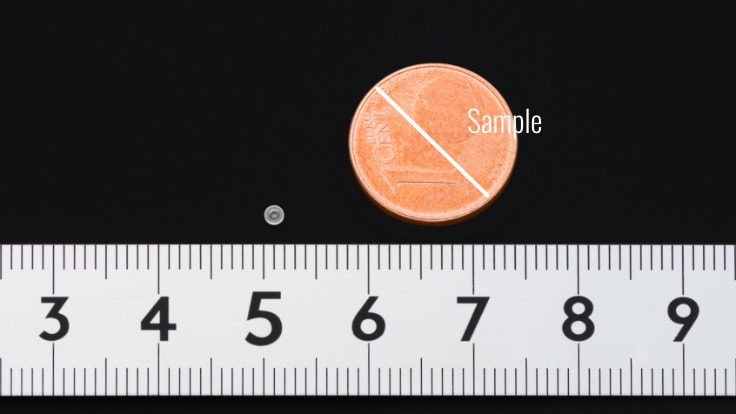

Tamron has realized an ultra-thin, small-diameter aspherical glass molded lens with a thickness of 0.1mm, equivalent to copy paper. This type of lens is expected to be used in optical systems such as wearable devices, robot eyes, and minimally invasive surgical cameras.

Tamron is evolving its lens processing technology to create lenses that can meet the ever-increasing demands for smaller equipment and higher resolution.

Technical features

-

FEATURE 1

Technology by glass molding technique that realizes high-precision shape processing and mass production at the same time

-

FEATURE 2

Achieved the same 0.1mm thickness as copier paper

-

FEATURE 3

Achieved a small diameter lens processing technology and coating technology for small surfaces

-

FEATURE 4

Adding an aspherical lens shape, realize a higher resolution lens while downsizing

-

Achieves thickness of 0.1 mm (CT scan image)

-

Small diameter of φ2.0 mm or less(CT scan image)

-

Small diameter of φ2.0 mm or less

Examples of applications

-

Compact and lightweight optical devices installed with robot arm

-

Video monitoring in a limited space

-

Lightweight wearable equipment

-

Low-invasive medical equipment

※The photo is for illustrative purposes only.

Technical information to be released

In addition to the technologies introduced here,

Tamron leverages various technologies for product development and to contribute to society.

In the future, Tamron plans to release the following technical information.

-

TECHNOLOGY 1

Large diameter lens with high precision surface accuracy

Technologies that maintain high surface precision for large lenses with diameter of φ140 mm