Actuator Technology

Optical lens system has various motors for zoom, iris and VC(Vibration Compensation).

Tamron constitutes an elaborated lens system, in accordance with required function and quality, by selecting an optimal motor among ultrasonic motor(ring type/standing wave type), brushless motor, stepping motor, voice coil motor and by developing actuator control system depending on each motor. Tamron’s strength is the system design with Actuator, Control Circuit and Software thoroughly by itself to integrate motor and optical system.

Tamron aim to solve many challenges in new applications and fields by utilizing the technology of quietness, high-speed, high-durability and high-torque cultivated throughout optical lens system.

Ultrasonic motors(USD, PZD)

High torque and controllability linked with optics

USD (Ultrasonic Silent Drive) and PZD (Piezo Drive) used in Tamron’s AF (autofocus) lens are independently developed.

Tamron worked to create an original actuator and it became the first company in the world to succeed in applying an actuator with piezoelectric ceramics elements to a lens drive, thus original AF lenses have been developed and released.

Ultrasonic motors having high torque, superior quietness and high holding force under a non-energized state, is not affected by magnetic force. While utilizing the characteristics Tamron realized significant volume reduction compared to the previous actuator structure.

Tamron has achieved great optimizations with optics by developing original control circuits and software that are able to fully derive ultrasonic motor’s performance.

Technical features

-

FEATURE 1

Realized stability and durability of torque under photographic lens environment

-

FEATURE 2

With original control system, high-precision (µm order) positioning control of lens group is achieved

-

FEATURE 3

Realized optimization of optics as originally developed actuator system (Motor, control circuit, software)

Note:Three features are common to the both USD and PZD.

Examples of applications

-

Various lens drives for large diameter lens and telescope

Lens driving motor for remote sensing, photographic lens and long-distance surveillance camera

-

Motor used in magnetic field environment

Lens driving motor used in magnetic field generated by MRI and in power plant

-

Lens for 4K/8K high resolution cameras

※The photo is for illustrative purposes only.

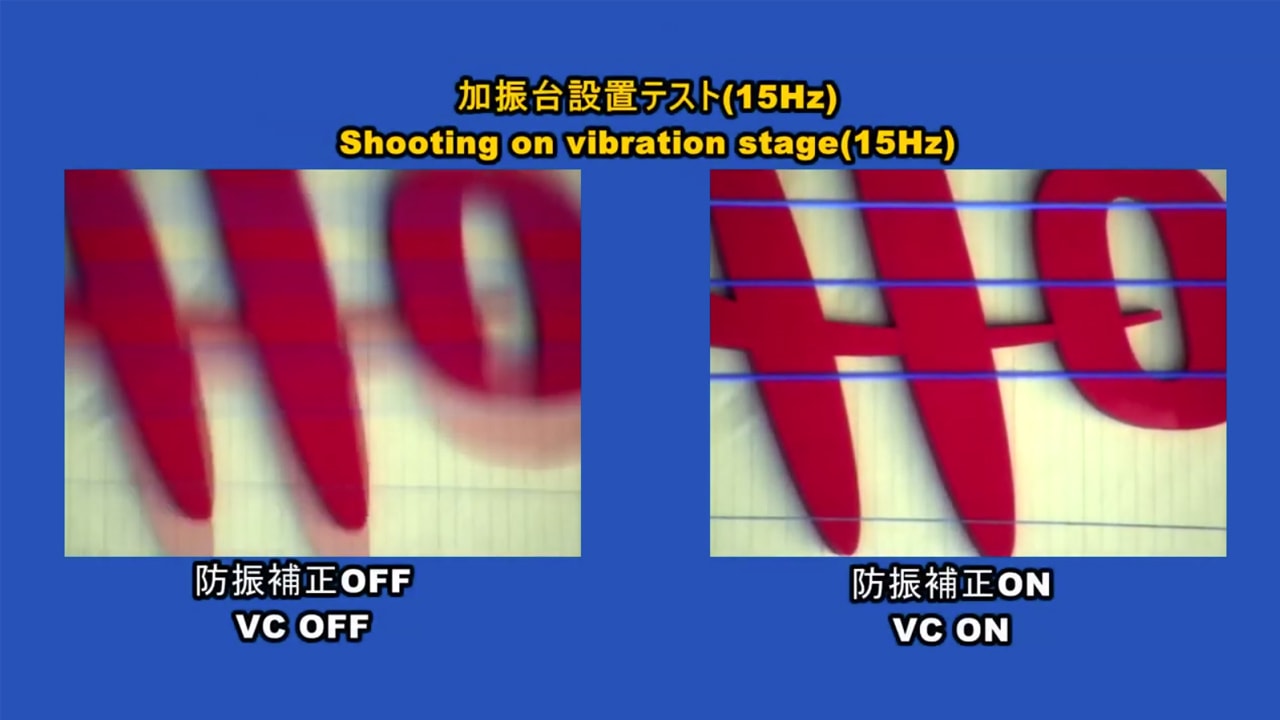

Optical VC (Vibration Compensation) system

Design systems thoroughly

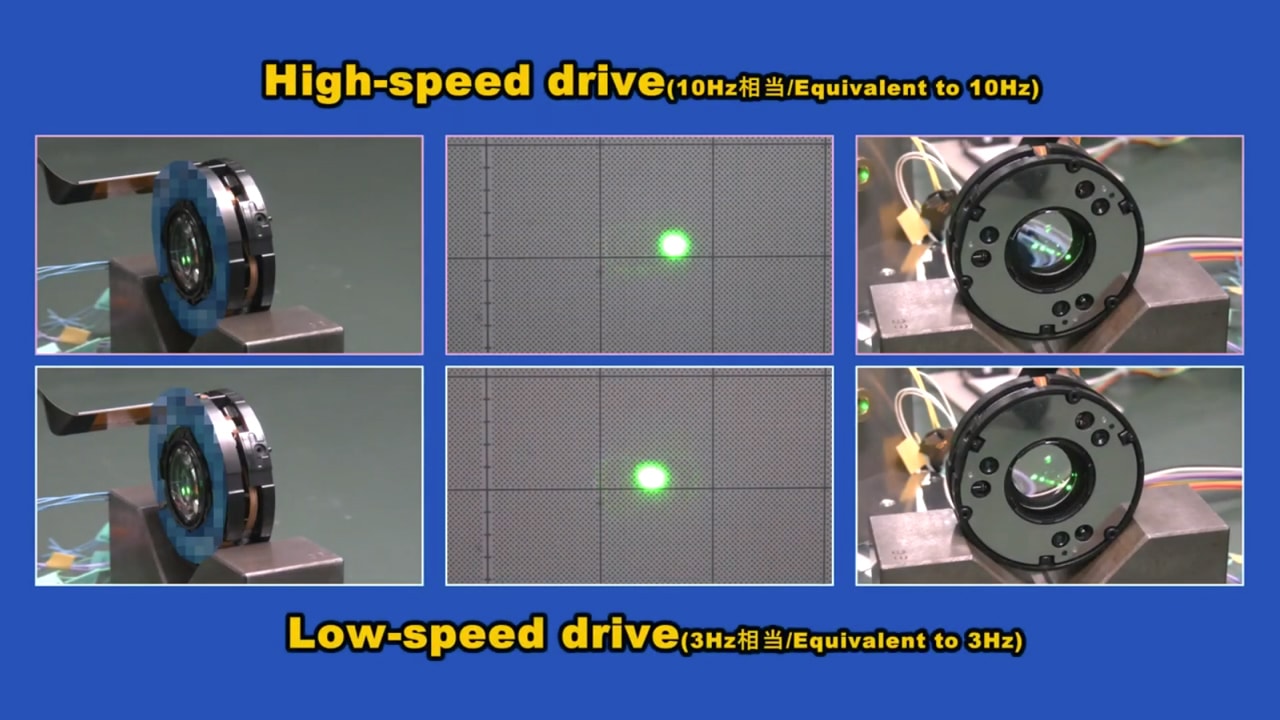

There are three types of camera-shake that require compensation and Tamron’s Vibration Compensation system is based on optical technology consisting of a three-axis voice coil motor, a position sensing hall sensor, and gyro-sensor for detecting angular vibration.

Vibration compensation cannot be realized with a motor independently. Lenses capable of having optical compensation work with feedback control that is responding to an angular velocity from the gyro sensor all while maintaining imaging performance during shooting.

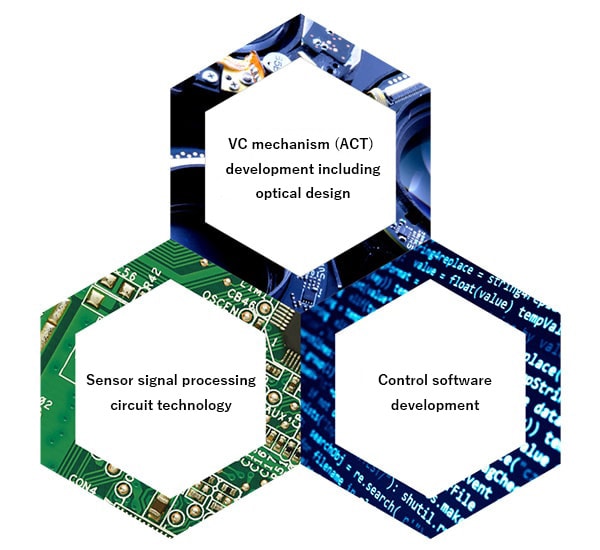

TTamron thoroughly designed the three aspects: “VC mechanism (ACT) development including optical design,” “Sensor signal processing circuit technology,” and “Control software development” and realized a fine drive and stopping accuracy in micron order.

With a unique AI algorithm, Tamron engages in seamless Vibration Compensation corresponding to various shooting conditions and vibration types. Moreover, a variable optical axis (beam bending) is possible by utilizing VC technology.

From now on, utilizing VC technology, in our view, will be widely used In products such as wearable devices, long- distance monitoring devices, and a moving equipment like robots.

Technical features

-

FEATURE 1

Expand VC technology and know-how cultivated through photographic lenses to various lens systems and applications

-

FEATURE 2

Comprehensively design systems with VC mechanism (ACT) development including optical design, Sensor control with analog circuit development, and Control software development

-

FEATURE 3

Developed Unique AI algorithm capable of VC for various shooting scenes

-

FEATURE 4

Variable optical axis (beam bending) utilized with optical axis compensation

-

Fusion of three technologies

Examples of applications

-

Vibration compensation for hand shaking: Photo shooting, binocular, compact telescope(monocular)

-

Vibration compensation installed in moving equipment: Robot (AGV, collaborative, arm, heavy machine)

-

Effect on coarse pointing and fine pointing by a variable optical axis: Variable optical axis for laser, Free Space Optics (FSO), Visible Light Communication (VLC)

※The photo is for illustrative purposes only.

Technical information to be released

In addition to the technologies introduced here,

Tamron leverages various technologies for product development and to contribute to society.

In the future, Tamron plans to release the following technical information.

-

TECHNOLOGY 1

Brushless motor

Compact and high-torque brushless motor development technology